- Home |

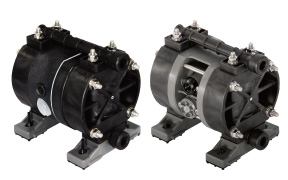

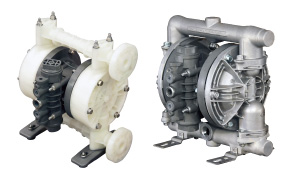

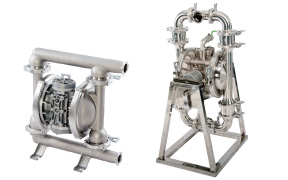

- Pump Manufacturing |

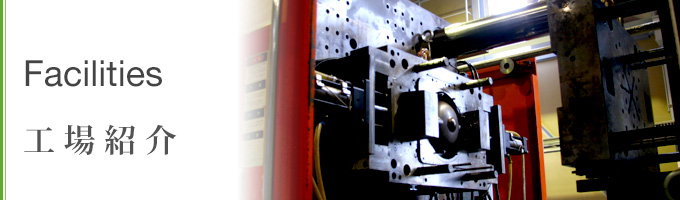

- Facilities

Sakura Manufacturing Plant

- Address

- 1-298-11, Osaku, Sakura-shi, Chiba 285-0802

- Site Area

- Approx. 7,000 m2

- Buildings Area

- Approx. 1,668 m2

The Sakura plant is the main manufacturing plant and warehouse of all YTS Pumps. Its greatest strength is the state of the art plastic injection molding room. This room is temperature controlled 24 hours a day, 7 days per week.

The plastic injection molding room has an independent heat-insulation structure, coupled a temperature control system so we are able to stabilize the quality of products. This system minimizes the changes in ambient temperature which would normally greatly affect the dimensional accuracy of plastic moldings.

We have introduced 14 different types of high pressure plastic injection molding machines ranging from 15 to 1,300 tons, enabling us to manufacture everything from small precision plastic parts to large pump casings.

Our employees continue to learn based on their own initiative and have also obtained nationally recognized qualifications specific to plastic injection molding. YTS can easily manufacture super-engineering type plastics such as PFA, PPS, PVDF, and PPG which can be difficult to design and mold.

The materials handling cutting and machining shop is also temperature controlled and this helps to ensure stable dimensional accuracy in the production of all pump parts.

Regarding the production and assembly of Diaphragm Pumps, we have introduced and strictly follow the TPS (Toyota production system). All line areas are designed to be compact and efficient and all employees have a highly tuned awareness of the quality improvement process.

All YTS Diaphragm Pumps are leak and operation tested prior to dispatch without the use of liquids. (Dry testing) To achieve a high standard of quality we have developed a series of computerized air-driven inspection machines, which enable YTS to carry out a very strict and highly accurate testing process. This not only allows YTS to manufacture and provide high-quality Diaphragm Pumps it also ensures there is no liquid residue remaining in any of the pumps after testing.

Yotsukaido Manufacturing Plant

- Address

- 598-10, Monoi, Yotsukaido-shi, Chiba 284-0012

- Site Area

- Approx. 1,400 m2

- Building Area

- Approx. 800 m2

The Yotsukaido plant as well as being the primary head office is the center of all sales, after sales, engineering and development. Pump and parts production also takes place as well as testing and research.

The Machining Section is tasked to produce trial parts or specialized and custom parts if requested by a customer. YTS can and is willing to create customized or specially designed pumps either in plastic of metal.

At the Yotsukaido Plant we also undertake meticulous repair of products based on specific supply and service contracts with some of our domestic partners.

Based on the type of service contract, we inspect pumps and parts and repair or replace them when necessary. Our experienced repair engineers are able to repair pumps precisely according to our customers' needs.