- HOME |

- Factory Information |

- Machining, Assembly & Inspection

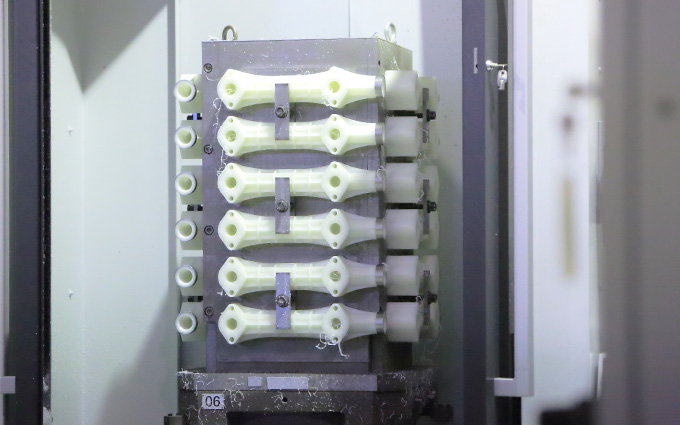

Machining

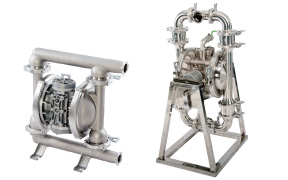

After the completion of the Plastics Injection Molding process, all machining work done on the pumps liquid wetted mating surfaces, holes and screw threads etc. is carried out internally by our highly skilled staff. YTS owns many Large Machining centers, CNC lathes and General-purpose lathes. YTS also prepares and carries out the machining work on many of the pump metallic components such as aluminum and stainless chambers and manifolds center rods and center discs etc.

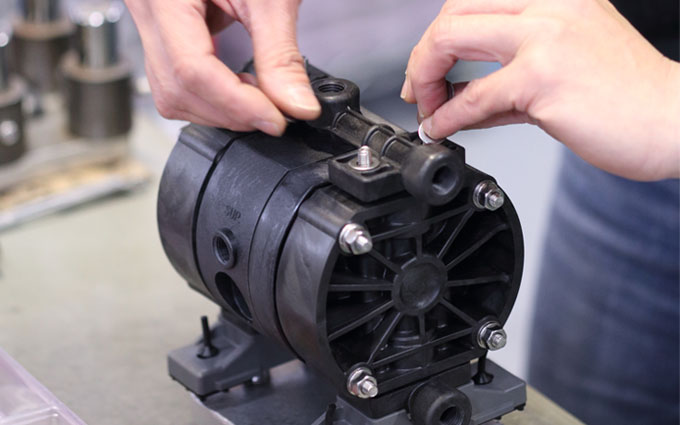

Assembly

YTS’s large range of Pumps are all manufactured and assembled at our Sakura facility. After assembly every pump goes through inspection and a series of tests including; vacuum pressure test, leak tests and pump operation tests. The majority of all pump parts are kept in stock, and pumps are manufactured following a strict Just-in-time manufacturing process ensuring very short lead times from order to dispatch.

Quality Control Management

YTS is an ISO9001 certified company. Together with strict environmental controls, and the use of high quality Japanese manufactured raw materials, YTS has also established a process of Kaizen in all our facilities offering employee training and process improvements. This all goes towards ensuring that we will produce the best possible products for our customers.